Degree Ultra High Temperature Graphite/Tungsten Heating Vacuum Furnace for Crystal Growth

Application Uses It can be used for bright quenching and annealing of alloy steel, tool steel, die steel, high-speed ste

Send your inquiryDESCRIPTION

Basic Info

| Heating Power | 50kw |

| Furnace Liner | Metal Liner or Graphite Liner |

| Convection Fan | Optional |

| Highest Temperature | 1320 Degrees |

| Temperature Control Accuracy | ±1ºC |

| Furnace Temperature Uniformity | ±5ºC |

| Pressure Rise Rate | 0.6PA/H |

| Air Cooling Pressure | 6 PA |

| Cooling Capacity | 500kg/4.5bar/1050-200 |

| Transport Package | International Standard |

| Trademark | SHLZK |

| Origin | Guangdong |

| HS Code | 8514191000 |

| Production Capacity | 100 |

Product Description

ApplicationUses It can be used for bright quenching and annealing of alloy steel, tool steel, die steel, high-speed steel, bearing steel, spring steel, stainless steel and other materials, or vacuum sintering of ceramic materials and hard alloys; vacuum brazing of metal materials, etc.

Structural features

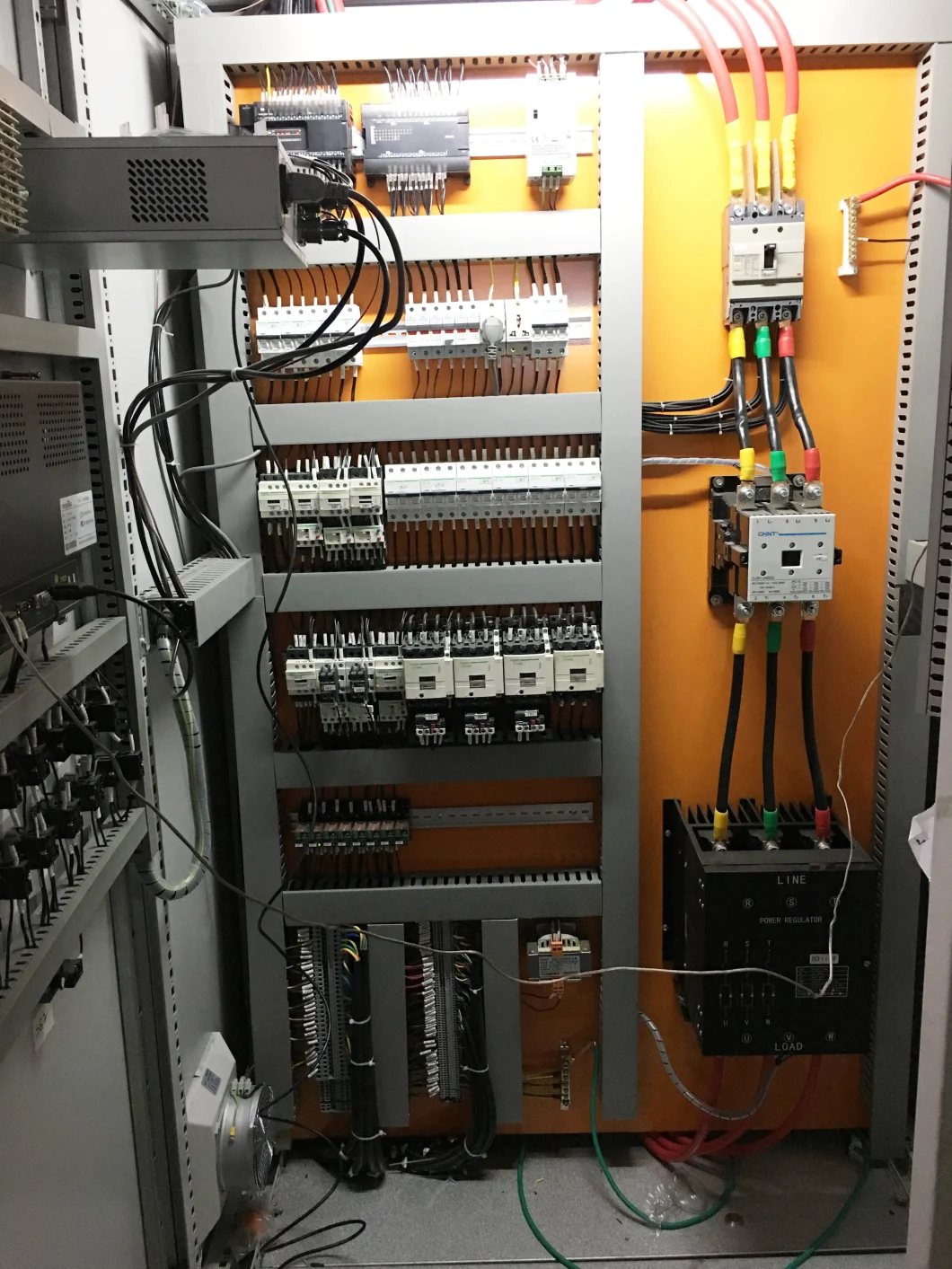

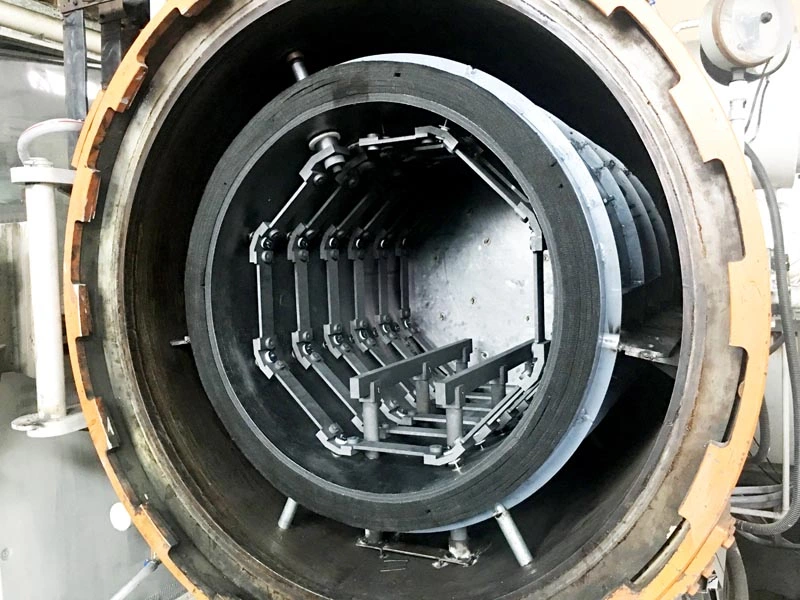

1. Horizontal structure, equipped with screw screw or hydraulic cylinder to drive the lifting mechanism;2. The motor and worm gear reducer are used to drive the horizontal running mechanism; the thermal gate valves between the chambers all adopt the four-bar linkage mechanism of the plug-in valve, which is reliable in sealing and stable in operation;3. The heating chamber adopts a composite heat shield composed of carbon felt and aluminum silicate fiber felt; the heating element is a graphite tube, which is easy to install and maintain, and has a low failure rate.4. The cooling chamber can use oil quenching and 2ba pressurized air cooling, which can be arbitrarily selected according to the material and size of the workpiece. The cooling chamber is equipped with an all-stainless steel air guide system and nozzles, which can effectively control the direction of the airflow and reduce the deformation of the workpiece.5. The choice of vacuum system can be selected between 4.0×10-1 or 6.7×10-3. The heating chamber can also be made into an all-metal heating chamber, and the heating element is a high-temperature molybdenum belt, which can meet the special requirements of heat treatment of materials such as titanium alloys, high-temperature alloys and special stainless steels.6. The electric control system adopts PLC and programmable temperature controller to realize three control modes of automatic, semi-automatic and manual, and the operation is flexible.

Technical parameter

| 1.Maximum temperature | 1320ºC |

| 2.Temperature control accuracy | ±1ºC |

| 3.Furnace temperature uniformity | ±5ºC |

| 4.Ultimate vacuum | 4x10^1Pa (6.7x10^3Pa when high vacuum is selected) |

| 5.Pressure rise rate hot room | 0.6Pa/h, cold room 0.6Pa/h |

| 6.Air-cooled pressure | cold room maximum inflation pressure (absolute pressure) 2bar |

Furnace structureHZC2 (two-room horizontal)

Dimensions

| Modle | Effective working size | Loading capacity | Heating power |

| HEC2 | 433450mmx300mmx300mm | 100kg | 40kw |

| HEC2 | 644600mmx400mmx400mm | 250kg | 65kw |

| HC2 | 755600mmx400mmx400mm | 350kg | 80kw |

| HZC2 | 966900mmx600mmx600mm | 500kg | 120kw |

| HZC2 | 12881200mmx800mmx800mm | 1000kg | 260cw |

Optional features

1. Furnace liner specificationsA round graphite furnace,B, direction graphite furnace. Gallbladder 2. Convective stirring Y (with convection fan),N (without heating convection fan).

Company introduction

APS Induction Technology (Taizhou) is a rare high-tech enterprise in China with international leading technology in induction melting and heating field. At present, the capacity of induction melting furnaces produced can up to 70 tons, and the power supply can reach to 50,000kw. The heating equipment can be used in carbon-based/ceramic-based composite materials, carbon fiber/silicon carbide fiber, high-performance ceramics, graphite, vacuum diffusion welding, vacuum hot pressing, vacuum melting, powder metallurgy, environmental protection and other industrial.In addition, we are also a professional manufacturer of power control boards, induction coils, water-cooled cables, yokes, and reactors. Compared with other manufacturers in China, we have outstanding advantages in product price, quality control, and delivery time.As an industrial equipment manufacturer with R & D capabilities, we keep seeking a balance between product economy and practicability in continuous innovation to ensure that we can provide the most valuable production solutions for each application, reduce costs for our users and help them improve production competitiveness.We hope to establish a more efficient, clean, low-carbon and circular green casting system by supplying stable, high-efficiency, energy-saving, safe and relatively cheap induction melting and heating equipment, and contribute to global energy conservation and emission reduction.

Related Products

-

![1064nm Yellow Laser Crystal YAG Rods D8mm*Length: 145mm ND: Ce: YAG Crystal for Laser Cutting Machine]()

1064nm Yellow Laser Crystal YAG Rods D8mm*Length: 145mm ND: Ce: YAG Crystal for Laser Cutting Machine

-

![Custom High Precision Quartz Plate / Fused Silica Optical Lens Quartz Crystal]()

Custom High Precision Quartz Plate / Fused Silica Optical Lens Quartz Crystal

-

![Optical Infrared Mgf2 Magnesium Fluoride Crystal for IR Application]()

Optical Infrared Mgf2 Magnesium Fluoride Crystal for IR Application

-

![Infrared Light Therapy Cold Laser Therapy Device for Pain Relief]()

Infrared Light Therapy Cold Laser Therapy Device for Pain Relief